The world around us is rapidly changing, everything is getting bigger and bigger and the demands are getting higher and higher. As a non-standard steel pipe manufacturing enterprise of science and technology, with technological innovation as core, from the railway, steel manufacturing military industry, nuclear energy, practical building etc, our expert engineers have developed a variety of special-shape steel pipe and pipe fittings solutions. Transform customer's needs into reality. We have provided specific products and production lines for the steel pipe production of users all over the world such as Canada, South Korea, Britain, UAE, Netherlands, Argentina, Russia etc.

Medium Frequency Thermal Expansion Pipe Technology and Application

Hydraulic two-step propulsion pipe-making machine unit was invented in the mid-1990s. In the research on the transformation of military-industrial enterprises, the inventor Fu Bingzhong found that with the development of power station boilers to high parameters, petrochemical plants to large scale and the long-distance fluid transmission, the demand for large-diameter seamless steel pipes is increasing. For the seamless steel pipes with diameter more than 508mm and diameter wall ratio (D/S)>25, it is difficult to produce by the pipe rolling machine unit. After years of careful design, repeated experiments, and many improvements. In 1996, the trial production of the pipe expanding machine was started and achieved success on December 25 of the same year. The technical indexes reached the design requirements, and the machine was put on the market in September 1997, and obtained the National patent at the same time.

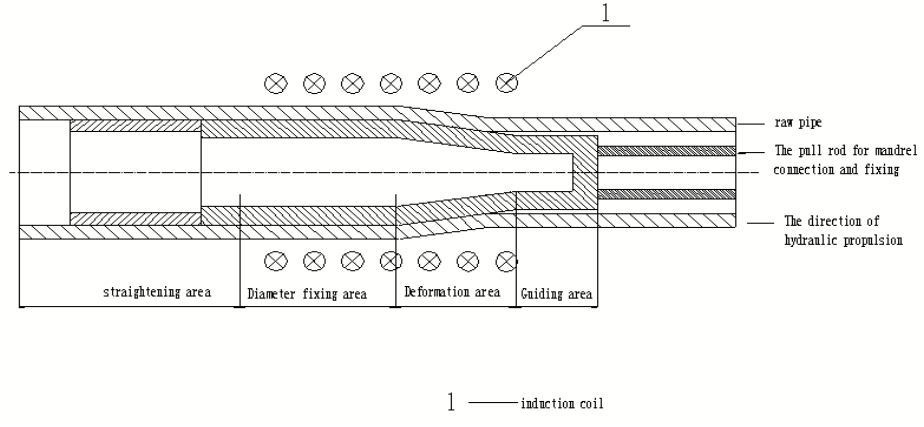

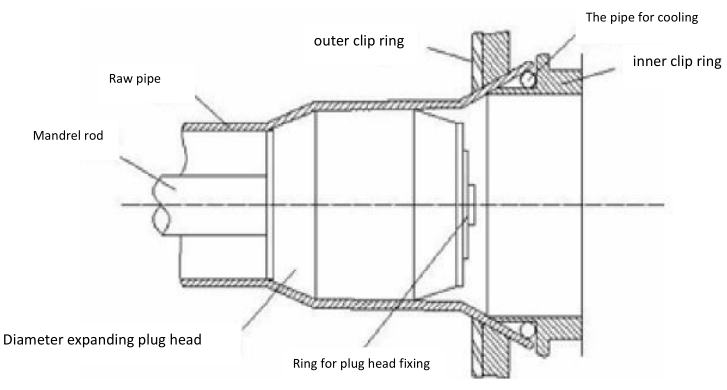

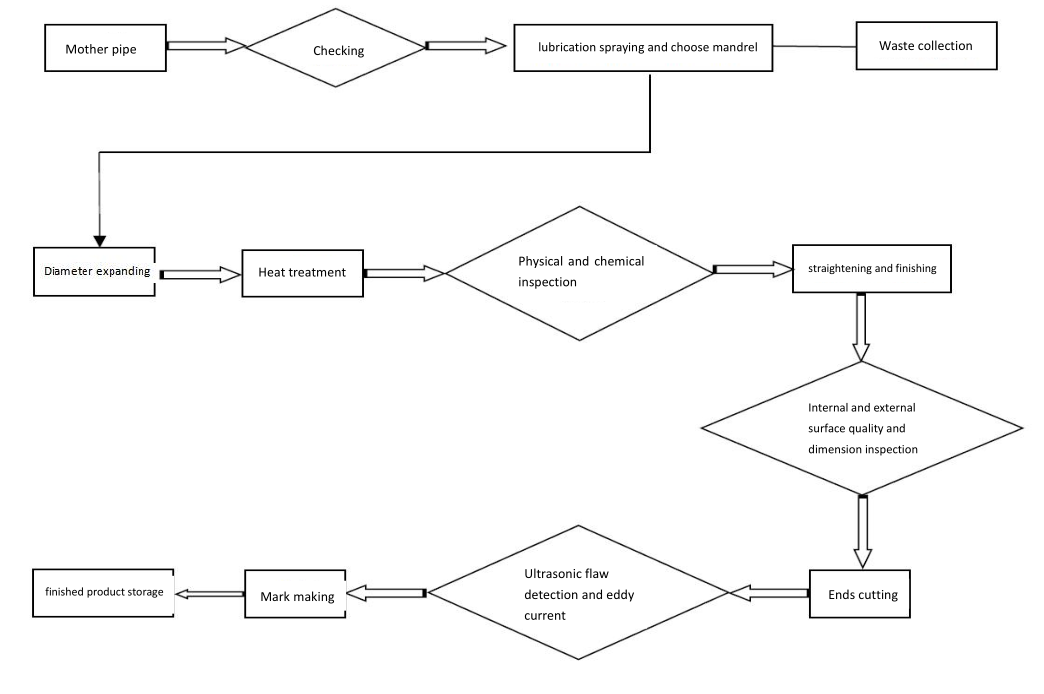

① Thermal expansion machine unit (hydraulic two-step propulsion pipe making machine)production process: it adopts the qualified finished steel pipes as mother pipes, to heat the mother pipes to the specified process temperature by medium frequency induction, and through the built-in mandrel under the continuous propulsion of the hydraulic cylinder to make the steel pipe is expanded to be the bigger diameter of seamless steel pipe through plastic deformation. This technology is designed to solve the problem of the large diameter and thick wall steel pipe production can not meet the market demand and all kinds of non-standard steel pipe and steel pipe diameter specifications are not complete. Especially suitable for small batch of multi-variety steel pipes production, it can meet the diameter expanding requirements with the different materials of steel pipe and various non-standard steel pipes.

② Because the steel pipe enterprises are restricted by the environmental protection of investment sites, it is impossible to have completed products variety, usually only there are several kinds of national standard specifications (such as φ219, φ325, φ426, φ530). For the users with the demand of non-standard steel with little quantity, due to at least hundreds of thousands or even millions to make one set of rollers (useless after using). Steel pipe companies cannot bear this kind of investment and time delays. Thermal pipe expansion machine unit is the only product to solve this problem.Thermal expansion process, especially mediate frequency thermal expansion process is a more economical choice, and also an indispensable, scientific and reasonable steel pipes production process. As long as the investment is several hundred thousand or several million, the steel pipe varieties and specifications of the original steel pipe manufacturers can be increased and enriched. The equipment with reasonable structure, accurateexpanding process, lower energy consumption, wide range of sources of raw materials adapt to the product specifications. In addition, the investment in equipment and workshops is relatively small. Which has long replaced the traditional drawing diameter expansion process in the pipe expansion industry. It has become an indispensable main production capacity to solve the shortage of large-diameter seamless steel pipes, seamlessly integrate large and medium-diameter longitudinal welded steel pipes, and enrich the series of steel pipe specifications.

③ The machine unit can be used in the thermal expansion production of all kinds of seamless steel pipe, straight seam welded pipe, coil pipe, etc. The expanded steel pipes have a wide range of materials, including carbon steel, alloy steel, stainless steel and other steel grades. The technology has been widely used in chemical engineering, military industry, power station, aerospace and Marine industry equipment manufacturing industry, has made an indispensable contribution to the steel pipe industry and energy construction.

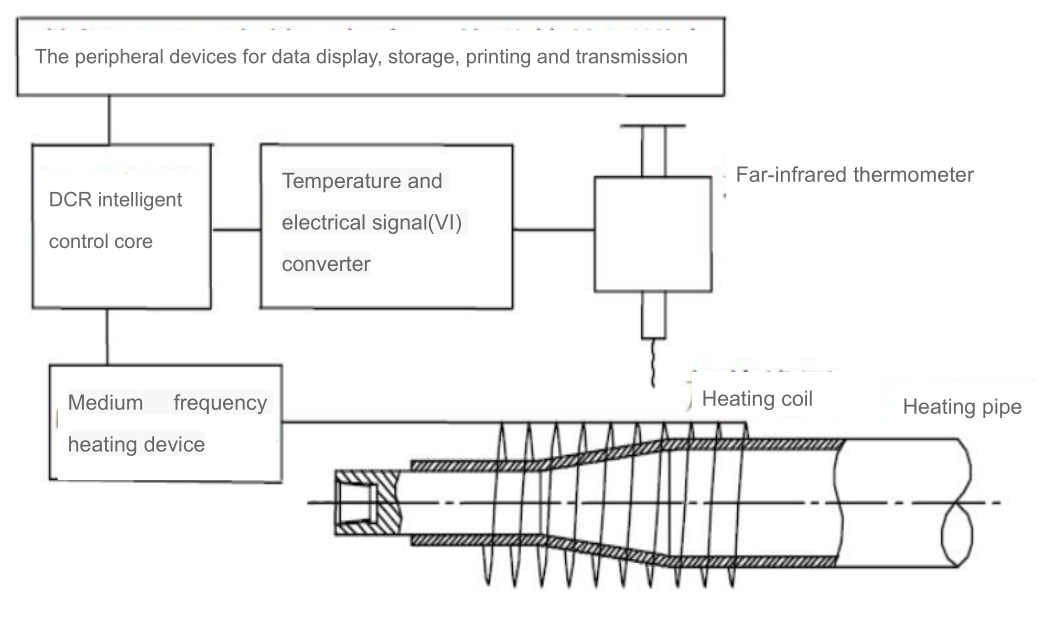

④ In order to meet the market needs of large diameter thick wall steel pipe, on the basis of the original patent product thermal expansion machine, our engineers Fu Bingzhong invented the four cylinders hydraulic two step-propulsion pipe expanding machine, cylinder two-step relay propulsion has reduced half of the expanding machine oil cylinder stroke, solved the processing limitation of oil cylinder stroke length from technology, greatly reduced the equipment cost of 1/3 ~ 1/2, and changed the original parallel thrust into frame type action point thrust, strengthened the stability of the equipment, improved the degree of freedom on the expanding machine equipment in operation, enhanced the reliability and the production efficiency of the equipment. At present, the thermal expansion machine unit hydraulic type two-step propulsion pipe machine has been successfully developed CNC pipe expanding machine, have realized intelligent PLC programming control, touch screen operation, remote control operation, real-time information storage and printing, video monitoring, environmental protection, safe operation. Make operation simpler, more efficient and greatly reduce labor and production costs. The high added value of the product has made the thermal expansion machine unit become the indispensable equipment for all steel pipe production enterprises. In China, it has formed a mature industry chain of thermal expansion steel pipeprocessing.There are millions of employees, and the total social benefits reach tens of billions.

1) Moderate thermal expansion heating temperature by mediate frequency is moderate, and the control is accurate, continuous and uniform, and it is not easy to produce cracks.

2) The heating method of mediate frequency thermal expansion process is continuous heating rather than local heating.

3) The metal in the deformation zone is under pressure in both axial and radial directions and under axial tension. It is not a unidirectional force.

4) High yield and low manufacturing cost (relative to cold drawing technology).

5) Strong adaptability of steel, such as carbon steel, carbon manganese steel, alloy steel, stainless steel pipes all can be thermal expanded.

6) It is flexible production, energy-saving and environmental protection, especially adopt to the demand with small-batch, variety, and short cycle.

7) The diameter changing of medium frequency thermal expansion can be achieved in one step, and the product size accuracy is high.

8) The inner and outer surface of the steel tube is of good quality and there is less iron oxide.

9) Thermal expansion pipes with large OD ( can be 1420mm), thin wall thickness(D/S up to 100), long length (Φ 914 mm steel pipe length can be up to 12 m).

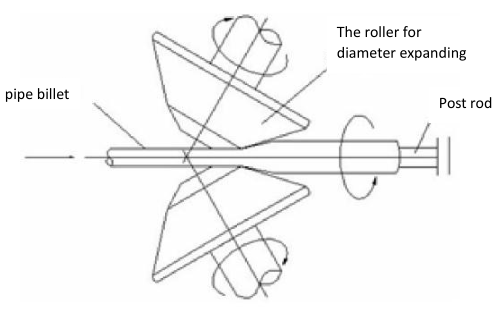

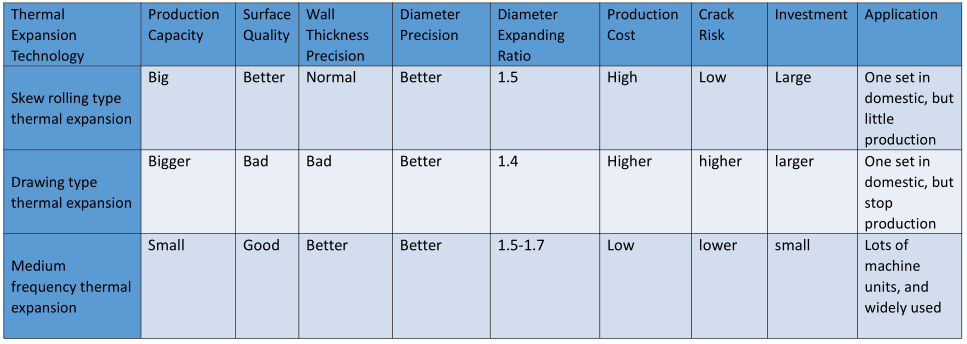

It includes three types of mediate frequency thermal expansion, skew rolling screw expansion and drawing type thermal expansion.

Since the first hydraulic type two-step propulsion pipe making machine (thermal expansion machine unit) was born in 1996, there are more than 600 sets of thermal expansion machine units of various models at domestic and overseas so far. In 2000, Tianjin steel pipe Group (TPCO) invested in the project after successful trial first, it becomes the first large state-owned enterprises that purchased thermal pipe expansion machine unit. In the same year, TPCO and the National Institute of Iron and Steel were organized to conduct a comprehensive test on the physical properties and chemical composition of the thermally expanded steel pipe. The test result is that the thermally expanded steel pipe and the original pipe have exactly the same indicators, which fully meet the national standards. Since then, our thermal expansion machine units have been distributed to all over the country's large and medium-sized steel pipe enterprises(companies), and continually exported to Canada, Netherlands, South Korea, Argentina, Indonesia, Brazil, Vietnam and other countries. Such as Tenaris(Argentina), Gana(South Korea), Kasco (South Korea), Bri-Steel (Canada), TPCO, An-steel Seamless Pipe Factory, Bao-steel Seamless Pipe Factory, Bao-steel Group, Hysteeltube, China North Heavy Industry, China Shipbuilding Heavy Industry Corporation (China Shipbuilding Industry Corporation), Sany Heavy Industry and other well-known enterprises of domestic and overseas.

Contact Information:

https://www.yaxingmachines.com

E-mail: alisa@yxgd.com.cn jane@yxgd.com.cn

Whatsapp: +86 13805342390

Address: Shuangyi road, Xinhua industrial zone, Decheng district, Dezhou city, Shandong province, China.

Sign In